At DyAnsys, patient safety is a primary concern and focus during product development as well as when products are in use. Chief Executive Officer Srini Nageshwar talked recently about the company's approach to patient safety as well as product development.

What is your commitment to patient safety?

Certainly, we meet the guidelines set by the appropriate medical device regulatory bodies. We obtain FDA clearance and CE Mark approval for our products. This requires extensive testing and documentation, which is important to us. We want to demonstrate that our products meet the highest standards of safety.

We are proud to say that we have exceeded the standard's requirement and appropriate regulatory compliance. Take sterilization for example. Sterilization validation and revalidation are carried out periodically as a regulatory requirement. However, we do additional testing on each batch sample even though it’s not mandatory. This ensures the highest level of safety for users.

We also make sure that testing for shelf life, validation, RoHS, biocompatibility and such are done at qualified and accredited laboratories. Our manufacturing plant is an ISO 13485 certified, FDA registered site and goes through a periodic audit by the appropriate regulatory bodies.

How do you ensure component quality?

The only way to have a high-quality product is to use high-quality components. This is why each and every component we use is selected carefully to ensure that it meets all the safety standards. Vendor selection plays a vital role in this. Our vendors go through a stringent evaluation process carried out by an expert team. Also, all the critical parts are inspected before we move to final production. The parts inspection is done by a qualified QA engineering team.

How do you ensure quality in manufacturing?

It starts by bringing only qualified parts into the inventory area. They are all stored and maintained in their specific environmental conditions.

The manufacturing is done by qualified and trained personnel. Still, we have inspections throughout the process to ensure that the process is being adhered to. We maintain records for each and every product for compliance.

An important part of ensuring quality is sterilizing products in small batches. This way, we ensure that we have fresh needles just before the product is shipped. We guarantee six months of shelf life. This is verified by actual testing, not just a statistical extrapolation. This is more time-consuming, but we feel it is necessary to ensure the highest quality product for patients.

How does logistics matter for patients?

There is a lot of discussion about the manufacturing process, but the process of getting the products into the hands of providers is also very important. We go to great lengths to ensure that the freshest products possible end up on the patient’s ear. The three components that need to be fresh are the batteries, adhesives and the sterilized needles. We procure the batteries from the manufacturer as we need them. The adhesive package is assembled as we ship the product, and the needles are sterilized on an ongoing basis. We make regular shipments, preferably weekly, from our manufacturing facility to our U.S. distribution center in Orlando, Florida.

We ask our customers to buy products as they use them rather than storing things on the shelf. As part of this, we are set up to ship in small quantities, even just one box. We don’t ask for a minimum order.

What do you do to ensure consistent treatment worldwide?

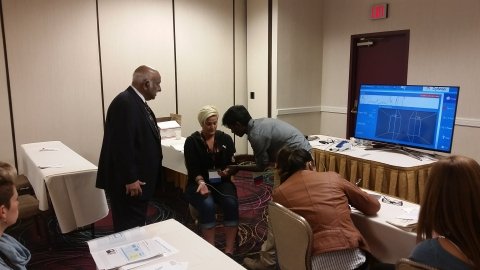

It starts with our training process. Our clinical specialists provide face-to-face and one-on-one training. We typically ask the provider to have three to five patients to treat. We do the first patient together with the provider. Then, we observe the provider administering the treatment to other patients and answer questions. To make the process go more smoothly, we have tools that We also have tools to allow the provider to prep the devices and ensure that they are working prior to application.

We also have materials to guide providers. One is a book on auriculotherapy that we recently co-published with Dr. Terry Oleson. This provides treatment locations for over 200 symptoms. These locations have been programmed into the controller for the programming/testing system and are capable of being displayed on a large screen in the treatment room. This will help providers to treat their patients consistently and minimize the training requirement.

What support do you offer providers?

We have a clinical support center that is staffed with medical professionals. They are accessible via toll-free numbers and video chats. They also visit the providers so they have personal relationships with them. They are available from 8 am EST to 6 pm PST. They are equipped to handle any questions that the customers may have.

This team also maintains ongoing contact through the dissemination of newsletters like this. It is also responsible for all DyAnsys communication with customers.